Since partnering with EE-Supply, we directly discuss complex matters with their team via phone/Zoom calls to collaboratively resolve issues, significantly boosting communication efficiency and order processing speed. Through this close collaboration, our order-to-shipment cycle has shortened to 5-7 days, tripling inventory turnover and capital utilization. This has substantially reduced our operational funding requirements. Our partnership with EE-supply has spanned over three years. During this period, thanks to the exceptional service provided by this outstanding team, our business performance has steadily improved. We look forward to a lasting collaboration with EE-supply.

Our Service Client Groups

E-commerce Sellers

Medium to Large Enterprises

Wholesalers

Supermarket Suppliers

Physical Retailers

E-commerce Sellers

Wholesalers

Physical Retailers

Supermarket Suppliers

Medium to Large Enterprises

Business Introduction

Procurement Consulting

In-depth Communication, Customized Services

Procurement Consulting

In-depth Communication, Customized Services

Business Categories

Are you often troubled by these challenges in cross-border procurement

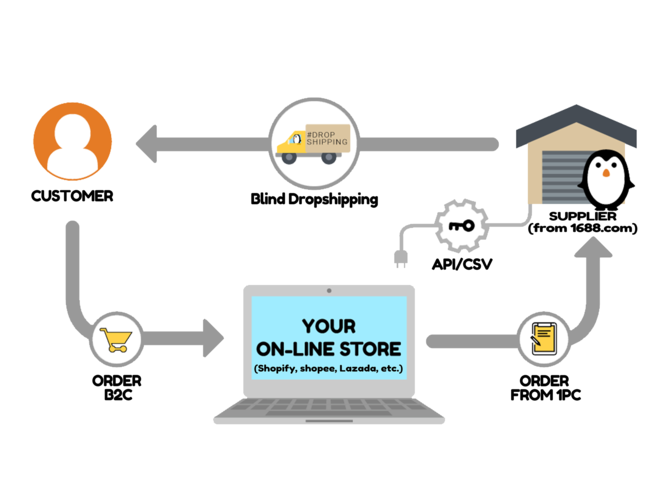

EE-Supply: Your One-Stop Chinese Sourcing Agency Service Platform

Our Advantages

Our Service Process

Consultation

Registration

Business Discussion

Sourcing

Placing Order

Refund to Account

Defective Returns

Inspection/Additional Services

Procurement

Payment of Order Amount

Payment of International Logistics

Genuine Products Stored

Shipping

Customs Clearance in Home Country

Receiving Goods

Consultation

Registration

Business Discussion

Payment of Order Amount

Placing Order

Sourcing

Procurement

Inspection/Additional Services

Genuine Products Stored

Refund to Account

Defective Returns

Customs Clearance in Home Country

Shipping

Payment of International Logistics

Receiving Goods

Client Testimonials

Since partnering with EE-Supply, we directly discuss complex matters with their team via phone/Zoom calls to collaboratively resolve issues, significantly boosting communication efficiency and order processing speed. Through this close collaboration, our order-to-shipment cycle has shortened to 5-7 days, tripling inventory turnover and capital utilization. This has substantially reduced our operational funding requirements. Our partnership with EE-supply has spanned over three years. During this period, thanks to the exceptional service provided by this outstanding team, our business performance has steadily improved. We look forward to a lasting collaboration with EE-supply.

After listening to my detailed situation, the EE-Supply team and I agreed on the product categories and quantities, then broke down the targets and timelines. Since I didn’t have a product selection team, they were also willing to help with the selection process.

The goal was set for around 20-year-old young women, with 1000 SKUs of clothing and jewelry, with 20 units per SKU for trial sales. We also set inspection standards and shipping timelines.

Product selection time: 5 days

Communicating with manufacturers, procurement, inspection, replacing OPP, tags, washing labels, stickers, product optimization services, and shipping: 20 days

A total of no more than 25 days to ship all products in time for my store opening.

What I remember most vividly is that during the 5 days of product selection, the team kept communicating with me, working overtime until 10 PM or even later every day to finalize the 1000 SKUs. They actually completed it in just 5 days, which greatly boosted my confidence.

Initially, I thought we would definitely delay the opening, but because the EE-Supply team went all out, they finished all the shipping 10 days in advance. All products arrived on time, and the opening went smoothly.

Later, I followed EE-Supply’s advice and hired a professional product selector to coordinate with their team. Our cooperation with EE-Supply became smoother and smoother, and we expanded from 1 store to 4 stores. They are like a professional local procurement department in China for my company, allowing me to confidently expand into new markets."

At the time, our product categories were too broad, with over 5000 SKUs spanning from men's clothing, women's clothing, lingerie, and more. This led to scattered competitiveness, and almost every category struggled to break through. We couldn’t form a core competitive product line on our online platforms.

The turning point came at an exhibition, where we had the privilege of meeting the EE-Supply team. After the exhibition, we visited their company.

After understanding our situation, they didn’t rush us into blind ordering; instead, they took the time to help us reassess our current situation.

They made a valuable suggestion: 'Rather than being broad and general, it’s better to focus on a core category, refine it, and build a brand for that category. Then, use the brand effect to drive other categories.' After this discussion, we decided to focus all our resources on jeans.

This decision turned out to be the right one.

Accompanied by EE-Supply staff, we visited over 30 jeans factories, establishing more solid partnerships with the manufacturers, continually optimizing fabric, design, and production processes. Our overall costs were reduced by 30%, which allowed us to create a brand product with our own core competitiveness.

Now, we’ve successfully entered the top five in the jeans category on a major online platform, and our offline wholesale business has also seen steady growth. EE-Supply is not just a supplier; they are a partner who has worked alongside us, facing challenges together and helping us break through the difficulties."

The turning point came when I was introduced to EE-Supply by a friend.

In our communication, I described the product development needs and pre-order quantities based on product images, and 2 days later, EE-Supply submitted a quotation with an ex-factory price of $5.20 per item.

I was shocked – the ex-factory price was less than half of the original price!

With EE-Supply’s advice and full support throughout the process, we quickly received product samples and the first batch of factory-produced products, and the quality met our standards.

The results were immediate. The same quality product, with the procurement price dropped from $12 to $5.20! This significantly relieved cost pressure and greatly increased our profit margin.

EE-Supply has truly become a partner, like a comrade. May our friendship last forever!"

At that time, we had up to 50,000 SKUs, and all our products were sourced from three local Chinese procurement service companies.

But everything had to be managed via Excel spreadsheets – manually entering orders, following up, auditing, checking inventory in and out, reconciling shipment numbers, and compiling statistics.

This led to very low efficiency, a high error rate, and excessive labor costs. Our procurement department alone had 12 people, and including inspection and warehouse staff, the total was over 20 people.

Then, through a friend’s recommendation, we started working with EE-Supply. That’s when we were introduced to their professionally developed procurement system.

At first, as someone used to Excel, I found it a bit unfamiliar, but after trying it once, I found it very simple, comprehensive, and efficient.

Especially for repeat orders, we could just click a button to import the products based on the system’s digital memory, eliminating the need to fill out and modify everything individually.

For us, the most direct change was in staff efficiency. Our procurement team shrank from 12 people to 3, and the warehouse team from 20 to 5, reducing our workforce by 75%.

However, overall efficiency actually increased, and management costs dropped.

Thanks to their professional procurement system and services, we no longer have to spend time organizing Excel sheets and can now focus on expanding sales.

Now, our cooperation with EE-Supply is running smoothly. They handle the backend procurement process while we focus on market development and sales. This clear industry division of labor allows everyone to do what they are best at, which is key to our steady growth and continuous expansion."

Initially, we encountered frequent problems with the samples we purchased ourselves—threads were tangled, sizes were inconsistent, and our apartment living room was filled with unsorted products. This made us realize how important a professional supply chain is. On a friend's recommendation, we began working with EE-Supply. Starting with a trial of 200 T-shirts, we were completely impressed by the first quality inspection report we received—high-definition photos highlighting every detail, thorough measurement data, and even colorfastness tests for the fabric.

Since then, EE-Supply has become our most reliable 'logistics department,' handling all the aspects that we 'didn’t' have in place. They’ve processed 13 batches, approximately 8,000 pieces of clothing, including quality inspections. Every batch’s quality inspection report is directly synchronized, making product quality clear and transparent.

The real test came last Black Friday. One of our vintage sweatshirts went viral on social media, with orders skyrocketing to over 400 pieces in a single day, far exceeding our processing capacity. As we anxiously waited, EE-Supply sent additional staff overnight, ensuring all orders were shipped within 48 hours and providing real-time logistics updates. That campaign resulted in our first-ever monthly sales exceeding 10,000 units.

Now, thanks to EE-Supply’s stable backend support—maintaining around 1,500 units of stock on average, with over 300 orders processed per day during peak sales—we can operate with great agility, fully focusing on studying fashion trends and marketing. For a light-asset startup team like ours, EE-Supply is not just a supplier; they are an extension of our 'supply chain department,' a key partner that has enabled us to transition from a cloud-based dream to a grounded, thriving business."

Initially, we encountered frequent problems with the samples we purchased ourselves—threads were tangled, sizes were inconsistent, and our apartment living room was filled with unsorted products. This made us realize how important a professional supply chain is. On a friend's recommendation, we began working with EE-Supply. Starting with a trial of 200 T-shirts, we were completely impressed by the first quality inspection report we received—high-definition photos highlighting every detail, thorough measurement data, and even colorfastness tests for the fabric.

Since then, EE-Supply has become our most reliable 'logistics department,' handling all the aspects that we 'didn’t' have in place. They’ve processed 13 batches, approximately 8,000 pieces of clothing, including quality inspections. Every batch’s quality inspection report is directly synchronized, making product quality clear and transparent.

The real test came last Black Friday. One of our vintage sweatshirts went viral on social media, with orders skyrocketing to over 400 pieces in a single day, far exceeding our processing capacity. As we anxiously waited, EE-Supply sent additional staff overnight, ensuring all orders were shipped within 48 hours and providing real-time logistics updates. That campaign resulted in our first-ever monthly sales exceeding 10,000 units.

Now, thanks to EE-Supply’s stable backend support—maintaining around 1,500 units of stock on average, with over 300 orders processed per day during peak sales—we can operate with great agility, fully focusing on studying fashion trends and marketing. For a light-asset startup team like ours, EE-Supply is not just a supplier; they are an extension of our 'supply chain department,' a key partner that has enabled us to transition from a cloud-based dream to a grounded, thriving business."

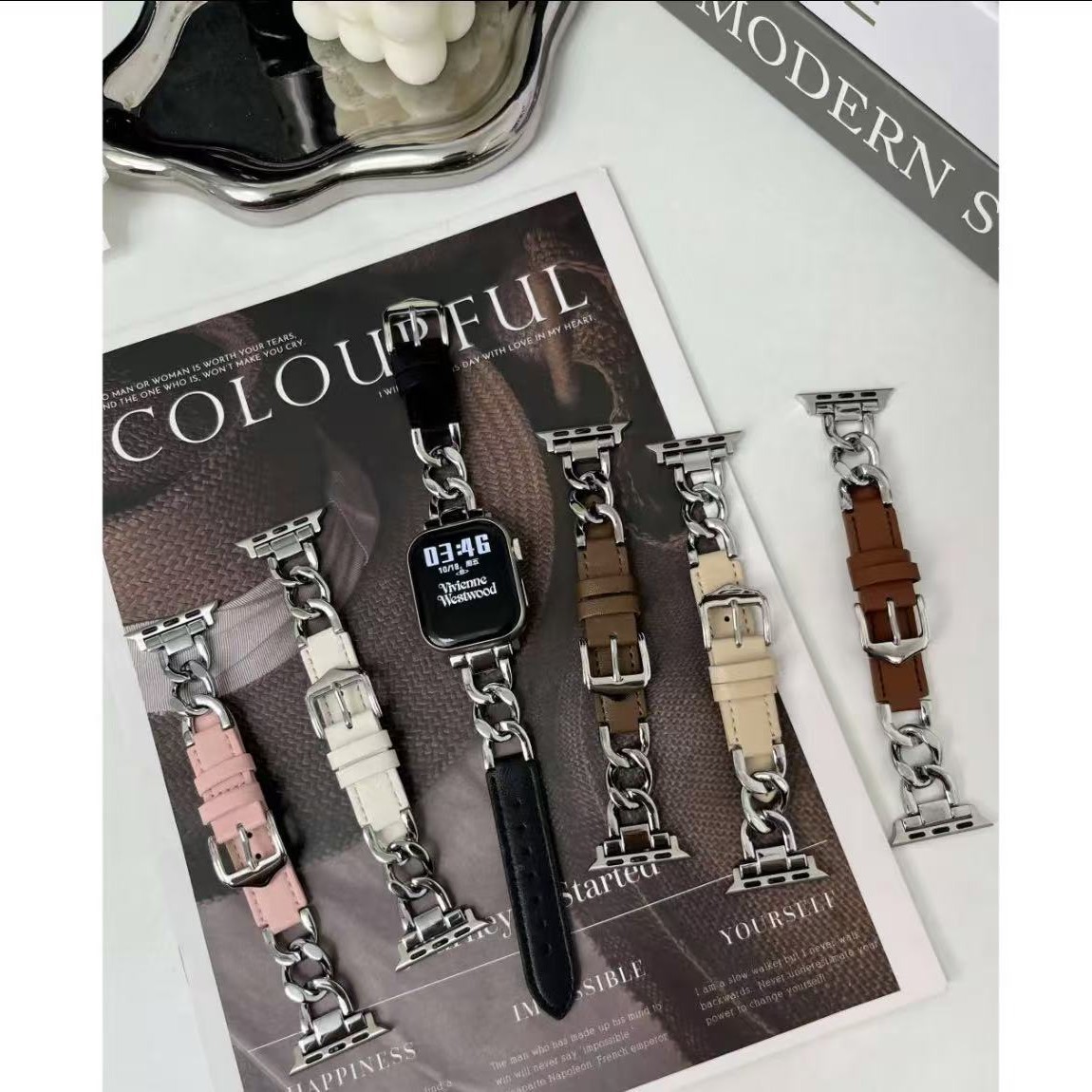

Product Showcase

Industry News

Partners

Chinese Language Hotline

Phone number

English Language Hotline

Phone number

Korean Language Hotline

Phone number

Japanese Language Hotline

Phone number

Russian Language Hotline

Phone number

Arabic Language Hotline

Phone number

Spanish Language Hotline

Phone number

Copyright © 2025 ee-supply.com All rights reserved.